CNC deep hole gun drilling machine maintenance

- 19 January 2018

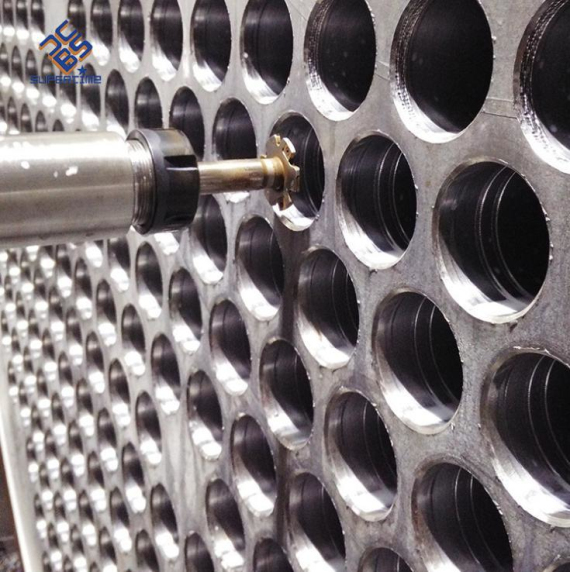

- CNC deep hole gun drilling machine maintenance

CNC deep hole gun drilling machine is an high efficient equipment for thick tube sheet processing. Equipment is usually expensive, so regular maintenance is vital for long time and stable running of machine.

Get the following skills!

Mechanical parts maintenance methods:

1.Main transmission chain regular maintenance: regularly adjust its tightness level, avoids turn lost phenomenon because of skidding strip; Check the constant temperature oil tank, regular temperature and add oil, clean filter; Regularly adjust displacement of hydraulic cylinder piston, after long term usage, clearance of tools clamping device influences clamping effect.

2.Regularly check ball screw, adjust axial gap of ball screw,ensure reverse transmission precision and axial rigidity; Check tightness between ball screw and machine frame.

CNC system maintenance:

1.Follow operation rules and daily maintenance methods.

2.Keep electrical and control cabinets doors closed if possible, to prevent mist, oil, dust or metal powder from entering circuit board or electrical components, causes bad insulation resistance and damage of circuit board and electrical components. Pay attention, even in summer hot temperature, It is a very undesirable way to open the door of the CNC cabinet, which will eventually lead to accelerated damage to the CNC system.

3.Regularly clean the heat dissipation ventilation system. Filter stoppage and dust accumulation will lead to high temperature in electrical cabinet.

4.Clean and change DC motor brush. Overwear influences motor working performance even motor damage.

More technical problems, welcome contact us!