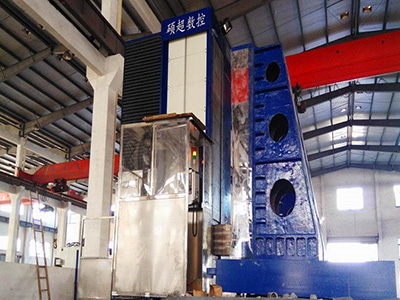

CNC Horizontal Drilling Machine WZ30

Machine application:

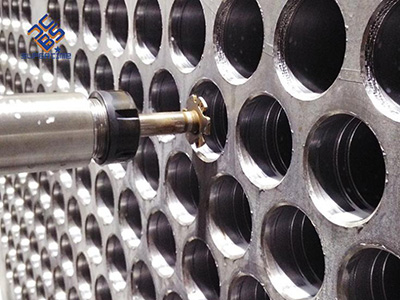

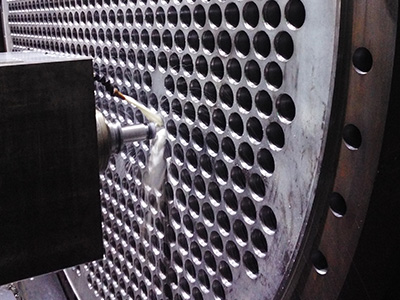

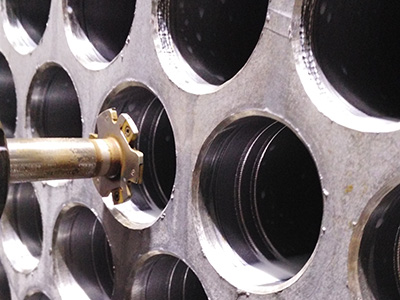

Machine is horizontal drilling machine, widely used in petrochemical, paper-making, heat exchanger etc, specially suitable for long shaft type flange drilling, tapping and milling. With advantages of high automation degree and precision.

Machine is flexible drilling milling machine, suitable for mass production.

Machine configuration:

Machine is mainly composed of longitudinal slide, vertical column, vertical slide, ram type drilling box, worktable, pneumatic system, cooling system, centralized lubrication system, electrical system, chip conveyor etc.

Machine features:

1. Horizontal structure, can easily remove chips.

2. Machine frame is welded from high quality cast iron, after artificial heat aging, acquires better stability. Bottom with adjustable parallel to adjust machine level.

3. Taiwan KENTURN inner cooling BT50 spindle, rotation speed 30-3000r/min.

4. WZ30 max. size of fixed worktable is 6000x9000mm, max. load-bearing is 70t. With T slots, V type clamping device to fix workpiece on worktable.

5. Pneumatic system blows spindle to supply air source.

6. Cooling system with filter, with high pressure inner cooling pump (2MPa, 40L/min) and low pressure out cooling. Recycle use of coolant.

7. With automatic lubrication system, prolongs machine service time and stable running.

8. CNC system SIEMENS 840D.

9. Plate chain type chip conveyor, width 470mm, length 6000mm. Coolant can be recycled after filtering.

10. With machine light, convenient for observation and operation.

11. With optical edge finder, easy to find workpiece position.

12. Machine components are world famous brands, such as linear guide rail, hydraulic pump, valves, spindle, servo motor, CNC system.

Parameter list:

| Name | Item | Value |

|---|---|---|

| Max.workpiece diameter(one time clamping) | Φ3000mm | |

| Max.workpiece length | 9000mm | |

| Worktable | T slot width | 28mm |

| Ram type drilling head | Quanlity | 1 |

| Spindle taper | BT50 | |

| Max.drilling diameter | Φ80mm | |

| Drilling depth | ≤400mm | Drilling depth/drilling diameter | ≤5 (U drill) |

| Spindle rotation speed | 30—3000r/min | |

| Max.tapping | M36 | |

| Spindle servo motor power | 30/45kW | |

| Spindle max.torque | 600Nm | |

| Hydraulic system | Hydraulic pump pressure/flow | 6.5MPa /25L/min |

| Hydraulic pump motor power | 3kW | |

| Pneumatic system | Compressed air pressure | ≥0.5MPa |

| Chip conveyor and cooling | Chip conveyor type | Plate chain type |

| Chip conveyor quantity | 1 | |

| Chip removal speed | 1m/min | |

| Chip conveyor motor power | 0.75kW | |

| Inner cooling pump motor power | 3kW | |

| Out cooling pump motor power | 0.75kW | |

| Inner cooling pressure | 2MPa | |

| Automatic lubrication system | Lubrication pressure | 2MPa |

| Lubrication point oil quantity | 0.1mL | |

| Lubrication period | 6-10min | |

| Electrical system | CNC system | SIEMENS 840D |

| CNC axis | 3+ 1 (spindle) | |

| Total power | 50kW | |

| Overall size | L x W x H | 15000X12500X6300mm |