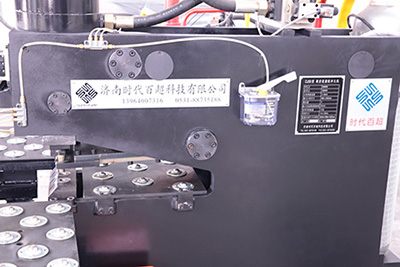

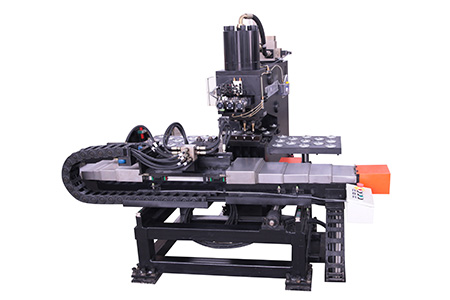

CNC plate punching machine CJ50

Machine application:

Hydraulic plate punching machine is high efficiency and accuracy equipment for steel plate processing, widely applied in steel tower, power transmission, or other industries using connection plates, machine realizes plate punching and marking functions.

Machine configuration:

1.Processing accuracy: meet GB2694-2003 demand.

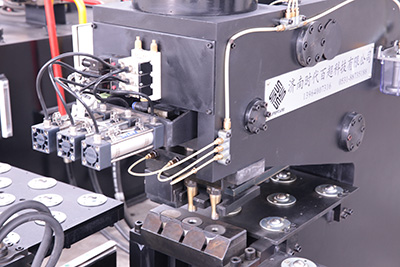

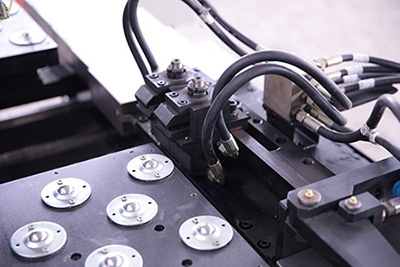

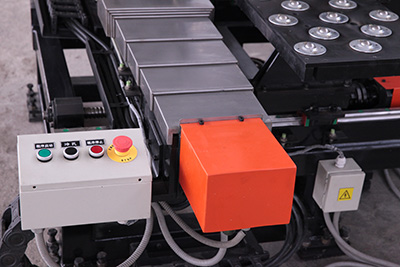

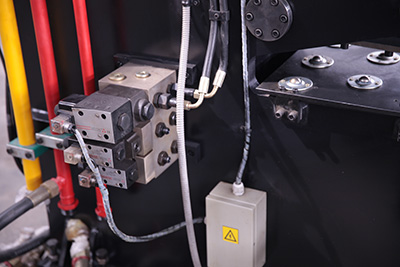

2.Main electrical control components, hydraulic, pneumatic are imported.

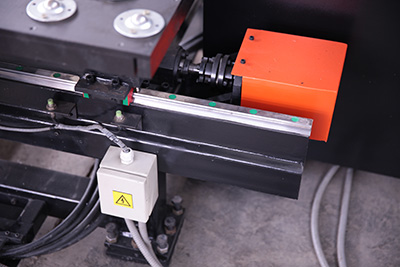

3.CNC axis: 2.

4.PLC: Japan Mitsubishi.

5.PC: DELL.

6.Servo system: Japan Yaskawa.

8.Pneumatic components: Taiwan AIRTAC.

9.Proximity switch: South Korea AUTONICA.

Machine features:

This machine has advanced electrical control system, easy programming and operation.

1. With special programming software and system control software, monitor of machine running and breakdown inspection functions.

2. Y axis adopts Japan Yaskawa servo motor, ensures quick positioning and positioning accuracy, A, B axes max. positioning speed is 12m/min, no-load accuracy is ±0.01mm.

3. Real time display of workpiece parameters, figures and programming.

4. With complete breakdown alarm system, can point out breakdown position and reasons.

5. Program can correct irregular workpice size.

6. Control system can directly converts lofting software or AUTOCAD program.

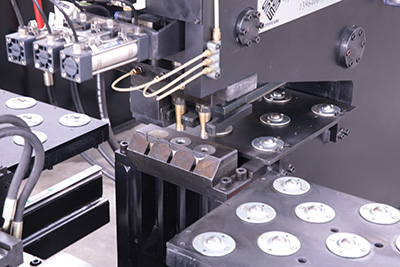

7. Press rod adopts hinge shaft structure with high structural strength, hydraulic cylinder provides pressure, big pressure and stable pressing.

Parameters list:

| Item | Unit | Values |

|---|---|---|

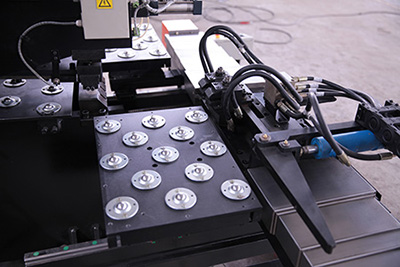

| Max. workpiece size | mm | 800×500(can enlarge processing range of X axis through re-positioning) |

| Workpiece thickness | mm | 3~8 |

| Max. punching diameter | mm | Φ25.5 |

| Mode number | pcs | 3 |

| Min. distance between hole center and plate edge | mm | 25 |

| Punching force | KN | 500 |

| Marking force | KN | 500 |

| Marking numbers | 14pcs size: 14x10mm | |

| Hydraulic block stroke | mm | 35 |

| CNC axis | numbers | 2 |

| Servo motor power | kW | 2×1.3 |

| Hydraulic pump motor power | kW | 15 |

| Total power | kW | 18 |

| Overall size | mm | 2000x1980x1520 |

| Max. Workpiece weight | t | 2.5 |

| Net weight | t | 4 |

| Processing accuracy | GB2694-2010 |