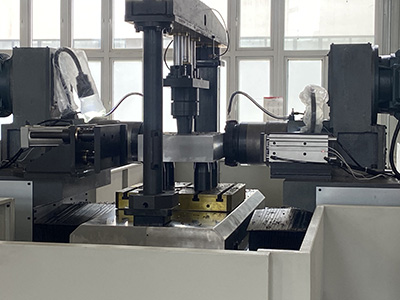

CNC double-sided milling machine BCTX-0707

Use of machine tool:

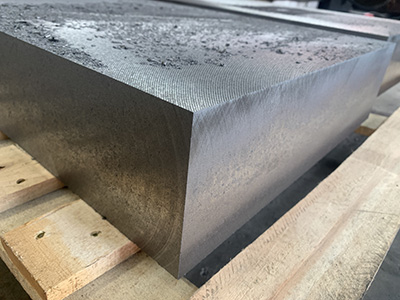

Numerical control double-sided milling machine is used for precision milling of moulds, mould base blank materials, hydraulic fittings, valve blocks, nonferrous metal processing and other industries, and it can automatically complete the machining of 4 surfaces with one touch start.

Features of machine tools:

1. NC double-sided milling machine adopts one-piece casting process to increase the overall rigidity of the machine tool and ensure stable performance.

2. Powerful milling spindle is adopted, and coarse and fine milling of four sides can be automatically completed in one clamping, so as to improve efficiency and reduce operation cost.

3. Precision servo index plate ensures the dimensional accuracy, parallelism, perpendicularity and squareness of workpiece.

4. Humanized control panel of numerical control system, simple operation and automatic diagnosis function.

5. Equipped with intelligent numerical control system with automatic measurement, tool setting, cutting, rough milling, fine milling, reversing and other efficient functions.

Machine tool parameters:

| Parameters Name | Items | Values |

|---|---|---|

| Effective processing range | Length * Width | 700×700mm |

| Rotary work table | Length * Width | 450×450mm |

| Milling power head | Number | 2 |

| Spindle taper hole | BT50 | |

| Max. milling cutter head | Φ200mm | |

| Spindle speed | 300r/min | |

| Spindle speed ratio | 1/4.8 | |

| Motor power of main shaft | 15kW | |

| Milling head min. - max. milling distance | 100mm-700mm |

The above parameters are for reference only, subject to the technical scheme, and support customized services of different specifications.