CNC Angle Drilling Marking Machine JX2532

Machine application:

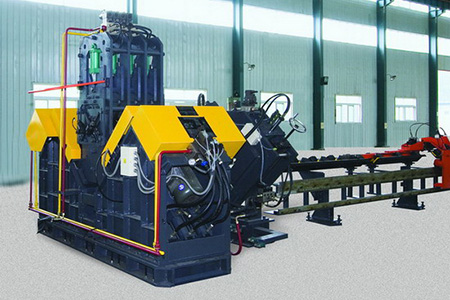

Machine is widely applied in power transmission, steel tower, railway, bridge building, for angle drilling and marking. This is an essential processing equipment in steel tower and steel structure manufacture.

Machine has 3 CNC axis, can realize servo control in gauge line and length directions, with advantages of high accuracy, easy operation etc.

Machine features:

1. Independent hydraulic and electrical CNC system, centralized control. Meanwhile for convenient mold and other parts adjustment, has decentralized control function.

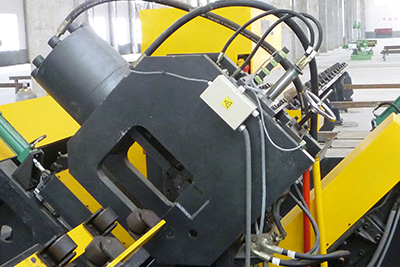

2. Main frame is steel plate welded, smaller size and weight, good rigidity. Hydraulic system controls actions through solenoid directional valve, simple structure and easy operation.

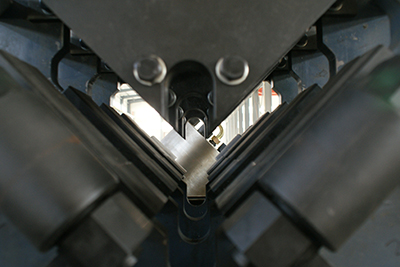

3. 2 drilling units, 3 sets of punching molds in each unit.

4. 4 letter groups, processes 4 workpiece in one nesting.

5. 3 CNC axis, for holes distance and two sides gauge line adjustment, high position accuracy;

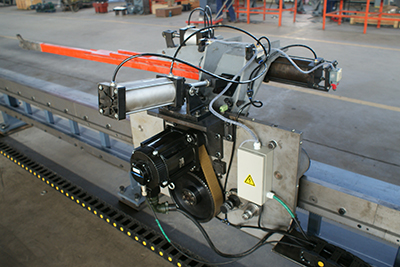

6. High accuracy of holes distance positioning, infeed part with encoder, for actual position feedback and error compensation, forms closed loop control.

7. Hydraulic, pneumatic, electrical components are world famous brands, reliable for long term usage.

Machine advantages:

1. CNC system of angle drilling machine, ensures drilling distance in longitudinal direction, angle 2 sides also adopt CNC, ensures two sides multiple gauge line drilling.

2. Standard configuration doesn’t include shearing unit, Supertime offers shearing unit for selection.

3. Machine is suitable for drilling different holes diameters, can drill angle width no more than 250mm, greatly improves processing efficiency in comparison with traditional processing methods.

4. Advanced software program:

A) SUPERTIME independently writes software program.

B) We can update software program according to actual production needs, in order to meet customers’ special demands.

C) Software program can read BOCAD, TEKLA lofting software, now we have developed program to realize connection with LANTEK.

D) This program can realize data exchange with ERP system.

5. Low maintenance cost:

A) Operators follow strictly our demands, low failure rates.

B) All electrical components are world 1-st class brand, easy to find supplier in any city.

C) Consumable parts we provide drawings accordingly, such as punching heads and dies, you can manufacture in own plant.

D) Over 20 years engineer team, responsibility of machine installation, commission and systematic training.

Parameter list:

| No. | Description | Unit | Parameters |

|---|---|---|---|

| 1 | Angle size | mm | 140×140×10-250×250×32 |

| 2 | Max. drilling dia. | mm | 40 |

| 3 | Spindle rotation speed | r/min | 180-560 |

| 4 | Spindle stroke | mm | 110 |

| 5 | Marking force | kN | 1000 |

| 6 | Letter groups and letter size | group/mm | 4 groups 14×10×19 |

| 7 | Drilling units numbers | number | 2 |

| 8 | Drilling heads number of each unit | number | 3 |

| 9 | Gauge line adjustment range | mm | 50-220 |

| 10 | Max. feeding angle length | mm | 12000 |

| 11 | CNC axis No. | number | 3 |

| 12 | X axis max. feeding speed | M/min | 40 |

| 13 | Overall size | m | 29×8.9×2.5 |

| 14 | Net weight | kg | 17000 |