The difference between CNC stepping motor and servo motor 8

- 16 November 2018

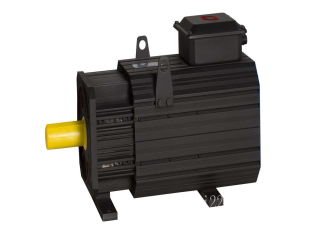

- CNC motor

15, is it possible to match domestic drives or motors with high quality motors or drives abroad?

In principle, it is possible, but the technical parameters of the motor must be clear before it can be used, otherwise it will greatly reduce the desired effect, and even affect the long-term operation and life. It is best to consult the supplier before deciding.

16. Is it safe to drive the motor with a dc supply voltage greater than the rated voltage?

Normally this is not a problem as long as the motor is running within the set speed and current limit. Because the motor speed is proportional to the motor line voltage, choosing a certain power supply voltage will not cause overspeed, but may occur driver and other failures.

In addition, it is necessary to ensure that the motor meets the minimum inductance requirements of the driver and that the current limit set is less than or equal to the rated current of the motor. In fact, if you can in your design of the device for the motor runs slower (lower than the rated voltage), it is very good at a lower voltage (hence the low speed) operation will make brush operation rebound is less, and brush or commutator wear small, low current consumption and long life. On the other hand, if the motor size *** and performance requirements require additional torque and speed, over-driving the motor is also ok, but the service life of the product will be sacrificed.

Mark

info@jntime.com

Tel/Whatsapp: +86 15863147078