About milling machines tools one

- 17 February 2019

- CNC Tools

Milling

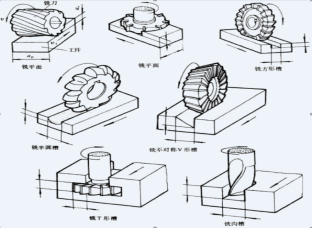

The rotary milling cutter is used for cutting. Milling is generally carried out on a milling or boring machine, suitable for machining surfaces, grooves, various shaping surfaces (such as spline, gear and thread) and special moulding surfaces. The feature of milling is: the teeth of the milling cutter with the final edge participate in the intermittent cutting periodically. The cutting thickness of each cutter tooth varies during the cutting process. Figure 1 is a few common milling processes.

Cutting speed v(m/min) is the circumferential speed of the milling blade. There are 3 ways of representation of feeding amount in milling: output per minute vf(mm/min) represents the displacement of workpiece per minute relative to the milling cutter; Where is the feed per revolution f(mm/rotation), represents the relative displacement of the workpiece with each rotation of the milling cutter; Mm per tooth feed af(mm/tooth) represents the relative displacement of the workpiece for each milling cutter turning a cutter tooth. Milling depth ap(mm) is the length of contact between the milling cutter and the workpiece measured in a direction parallel to the axis of the milling cutter. Ae (mm) is the depth of the contact arc between the cutter and the workpiece measured perpendicular to the axis of the milling cutter. The cutting speed of medium carbon steel milling with high speed steel milling cutter is generally 20 ~ 30 m/min. Use carbide milling cutter can reach 60 ~ 90 m/min.

Mark

info@jntime.com

Tel/Whatsapp: +86 15863147078